Ensuring Semiconductor Performance through Advanced Hydrogen Vapour Permeability Management

Click

on the image to download a print quality scan

In semiconductor manufacturing, managing hydrogen vapour permeability is crucial to preserving the integrity of processes such as deposition, etching, annealing, doping and passivation. Uncontrolled hydrogen permeation can degrade semiconductor devices, particularly in technologies like MOSFETs, where long-term reliability is essential.

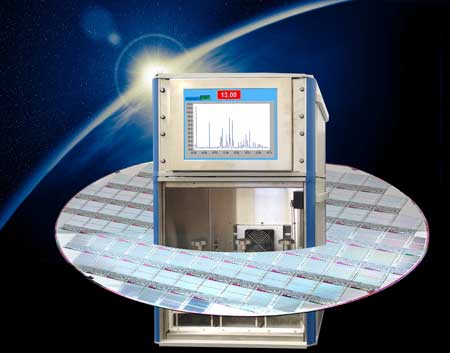

Versaperm’s latest vapour permeability measurement equipment offers a fast, precise solution to this challenge. Capable of testing and measuring hydrogen permeability across a variety of materials, components and systems, it ensures that hydrogen does not lead to contamination problems or semiconductor performance or device quality.

With accuracy ranging from Parts Per Million (PPM) to Parts Per Billion (PPB), Versaperm's equipment can simultaneously evaluate multiple samples, processes or enclosures. The system can also provide comprehensive environmental control, handling temperatures from -80°C to over +1000°C, along with adjustable pressure and partial pressure.

Effective vapour permeability management plays a pivotal role in preventing contamination during epitaxy and passivation processes, maintaining consistent vapour deposition and controlling doping concentrations. Minimizing hydrogen permeation through encapsulation materials is essential for device longevity, while managing hydrogen outgassing is critical for processes that require ultra-high vacuum conditions.

Versaperm systems can measure not only hydrogen but also a wide range of vapours commonly found in electronics manufacturing, including hydrocarbons, solvents, CO2 and other gases. The ability to measure vapour permeability in semiconductor manufacture is vital, as the many of the processes processes can significantly impact a material’s vapour barrier performance.

For companies that require occasional testing, Versaperm also provides a specialized laboratory service to meet these needs without the need for dedicated in-house equipment.

ENDS

Please send

any sales enquiries to Christopher Roberts, Versaperm Limited ,

10 Rawcliffe House, Howarth Road, Maidenhead, Berkshire, SL6 1AP, UK, Tel: +44 (0) 1628 777668,

e.mail info@versaperm.co.uk

Web http://www.versaperm.co.uk

For further

Press Information please contact Gerry Palmer @ the Palmer & Rose

Partnership. Tel +44 (0) 1494 637499, e.mail gerry@palmer-rose.co.uk.

|